Ledden actuator

LHE SERIES

Electric Valve Operators

The Ledeen LHE Series Operators utilize a full range of electric motor drives providing a wide selection of torques and speeds. Interlocked reversing starter assemblies are available either integrally or separate in explosion proof or weatherproof rated housings. Pushbuttons and indicator lights are also available. Other optional electrical accessories are available for specific application requirements.

LHP SERIES

Pneumatic Valve Operators

The Ledeen LHP Series Operator is mechanically interchangeable with the LHE and utilizes air or gas as its primary power source. A variety of motor/transmission combinations offers a full range of torque and speed outputs. Standard pneumatic control packages are integrally mounted and piped on the operator thereby simplifying field installation. These packages range from simple manual control to complex computer or telemetrically signalled control for use in process systems.

LHH SERIES_

Hydraulic Valve Operators

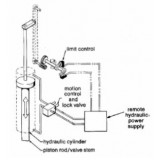

The Ledeen LHH Series Operator is a modular unit designed for use with either a central hydrau

The charts shown below illustrate the model numbering system. The first 3 or 4 letters describe the type of actuator and the operating system. This is arrived at by referring to the description of the individual products. The second group of numbers represent the size of actuator unit, its cylinder diameter and scotch yoke characteristics.

The size of actuator is determined by the torque or thrust requirement of the.valve. With knowledge of the valve requirement the optimum actuator can be selected from the appropriate performance data.

The remaining digits refer to power pack type and size. This is determined by speed of operation requirements; consumption limitations; supply available; etc. Other digits will identify alternative or fail safe systems, and include spring return units; accumulator or reservoir energy storage.

The examples below show typical Ledeen actuator model numbers and how they are built up.

For natural gas applications where the pipeline medium is used to power the actuator via gas over oil tanks. These gas/oil tanks containing hydraulic fluid, are arranged to accept filtered gas via a suitable control system. The gas, at line pressure, acts upon the hydraulic fluid power to drive the previously described Scoth-yoke mechanism.

The torque output of this type of actuator varies with the line pressure available as does the torque requirement of the main line valve. In all other respects the gas/oil units are identical to the previously described units and all accessories such as limit switches, limit valves etc. can be applied.

LTG/O 15006, LTG/O 20006, LTG/O 32506, LTG/O 20009, LTG/O 40009, LTG/O 350012, LTG/O 50012, LTG/O 60015SA, LTG/O 60015DA, LTG/O 70015SA, LTG/O 70015DA, LTG/O 80015SA, LTG/O 80015DA

Operating from a Central Hydraulic System or from remotely located powerpack. Pressure ranges up to 5000 psi. Thrust and speed control, limit switch pack and motion control are all identical to those employed on the LCP/H and LCE/H 'C' Series actuators.

LCP-200XX, LCP-250XX, LCP- 325XX, LCP-400XX, LCP-500XX, LCP-600XX, LCP-700XX, LCP-800XX, LCP-1000XX

LCE-200XX, LCE-250XX, LCE- 325XX, LCE-400XX, LCE-500XX, LCE-600XX, LCE-700XX, LCE-800XX, LCE-1000XX

Performance Data LCH 'Cyl' Series Actuators

Direct Hydraulic (L TH) 'T' Series Actuator. Operating from a central hydraulic system or from a remotely located power pack. Standard pressure range up to 2000 psi. High pressure range up to 5000 psi.

LTH 15006, LTH 20006, LTH 32506, LTH 20009, LTH 40009, LTH 20012, LTH 350012, LTH 50012, LTH 40015, LTH 60015SA, LTH 60015DA

Operating from any standard single or three phase electricity supply. Employing a certified electric motor driving an integral hydraulic pump. The unit can be supplied with integral motor starter incorporating control transformer and local control all housed in an explosion proof enclosed. Torque and speed control are incorporated in the Hydraulic Circuit which is essentially the same as the L TP/H unit. Again by the addition of a hydro-pneumatic accumulator a fail-safe action can be incorporated.

Operating from any standard single or three phase electricity supply. Employing a certified electric motor driving an integral hydraulic pump. The unit can be supplied with integral motor starter incorporating control transformer and local control all housed in an explosion proof enclosed. Torque and speed control are incorporated in the Hydraulic Circuit which is essentially the same as the L TP/H unit. Again by the addition of a hydro-pneumatic accumulator a fail-safe action can be incorporated.

Pneumatic/Hydraulic (LTP) 'T' Series Actuator. Operating from air or natural gas, high or low pressure (50 psi min). Employing a Pneumatic motor driving an integral hydraulic pump, developing up to 2000 psi hydraulic pressure. By use of readily adjustable relief valves the torque output is variable enabling the actuator to closely match the valve load requirement.

By varying the basic actuator frame, the capacity of the Pneumatic/Hydraulic Power Pack, and the final output pressure the optimum actuator can be selected for the specific valve application. By the addition of a hydro-pneumatic accumulator, fail-safe action can be stored in the hydraulic circuit. This fail-safe operation is reinstated automatically when the valve is returned to the operational condition.

The units previously described and illustrated are of the tandem or 'T' Series configuration and have sufficient torque output to accommodate valve sizes in general terms 40" - 48" Class 600 ( 1.2m in lbs of torque), depending on type and seating arrangements, actual line pressure, etc. To accommodate the largest % turn valves being manufactured to the highest pressure classes the Ledeen actuator range includes the QUAD or 'Q' Series actuator, comprising a double torque arm and four cylinder configuration, either single or double acting.

The 'Q' Series actuator can be adapted to any type of power medium previously described by the addition of the suitable power pack.

i.e. Direct Pneumatic (LQP)

Direct Hydraulic (LQH)

LQH 60021SA

LQH 80021SA

LQH 80021DA

LQH 100021SA

LQH 100021DA

Pneumatic-Hydraulic (LQP/H)

LQP/H 60021SA

LQP/H 80021SA

LQP/H 80021DA

LQP/H 100021SA

LQP/H 100021DA

Electro-Hydraulic (LQE/H)

LQE/H 60021SA

LQE/H 80021SA

LQE/H 80021DA

LQE/H 100021SA

LQE/H 100021DA

Gas Over Oil (LQG/Q)

LQG/Q 60021SA

LQG/Q 80021SA

LQG/Q 80021DA

LQG/Q 100021SA

LQG/Q 100021DA

All power packs, limit switch packs, limit

All Ledeen 'T' and 'Q' Series actuators employ the scotch-yoke principle for converting linear force into torque. The scotch-yoke mechanism is manufactured as the "Tandem" or 'T' Series unit with a single torque arm and one or two cylinder configuration and for larger valves the "Quad" or 'Q' series unit, with a double torque arm and four cylinder configuration.

The scotch-yoke principle is particularly well suited for the operation of ball, plug and butterfly valves .in that the maximum torque output is at the beginning and end of stroke. This distribution of effort matches the characteristic of these types of valves, where the highest torque is required for seating and unseating.

The 'T' and 'Q' Series units employ stroke adjustment, to allow accurate valve port and seat alignment, as well as speed control and torque limiting. The actuator stroke is controlled by limit switches in the case of electric control via solenoid valve or local push button; by limit valves when the unit is controlled from a pneumatic signal. The explosion proof switch pack unit contains up to 10 SPDT switch elements, and can be equipped to give position feedback. Manual operation for the direct pne

Showing 1 to 10 of 10 (1 Pages)